30

дек

Contents • • • • • • • • • • • • LCD UNIT Let us look at a pin diagram of a commercially available LCD like JHD162 which uses a HD44780 controller and then describe its operation. Pin Number Symbol Pin Function 1 VSS Ground 2 VCC +5v 3 VEE Contrast adjustment (VO) 4 RS Register Select. 0:Command, 1: Data 5 R/W Read/Write, R/W=0: Write & R/W=1: Read 6 EN Enable. Falling edge triggered 7 D0 Data Bit 0 8 D1 Data Bit 1 9 D2 Data Bit 2 10 D3 Data Bit 3 11 D4 Data Bit 4 12 D5 Data Bit 5 13 D6 Data Bit 6 14 D7 Data Bit 7/Busy Flag 15 A/LED+ Back-light Anode(+) 16 K/LED- Back-Light Cathode(-) Apart from the voltage supply connections the important pins from the programming perspective are the data lines(8-bit Data bus), Register select, Read/Write and Enable pin. Data Bus: As shown in the above figure and table, an alphanumeric LCD has an 8-bit data bus referenced as D0-D7. As it is an 8-bit data bus, we can send the data/cmd to LCD in bytes. It also provides the provision to send the data/cmd in chunks of 4-bit, which is used when there are limited number of GPIO lines on the microcontroller.

Register Select(RS): The LCD has two register namely a Data register and Command register. Any data that needs to be displayed on the LCD has to be written to the data register of LCD. Command can be issued to LCD by writing it to Command register of LCD. This signal is used to differentiate the data/cmd received by the LCD. If the RS signal is LOW then the LCD interprets the 8-bit info as Command and writes it Command register and performs the action as per the command. If the RS signal is HIGH then the LCD interprets the 8-bit info as data and copies it to data register. After that the LCD decodes the data for generating the 5x7 pattern and finally displays on the LCD.

Hi.can i get some tutorials on interfacing servo motors with lpc2129 using 'PWM'. Writing the assembler code(assembly programming) for LPC2129 in KEIL. May 18, 2014 Hi, I have interfaced AT25F1024 SPI-EEPROM with LPC2129. The code is to write a single byte of character in to the AT25F1024 & again read the same byte & display on the lcd. I know how to display on the lcd. But i don't know how to write & read a byte from AT251014.

Read/Write(RW): This signal is used to write the data/cmd to LCD and reads the busy flag of LCD. For write operation the RW should be LOW and for read operation the R/W should be HIGH.

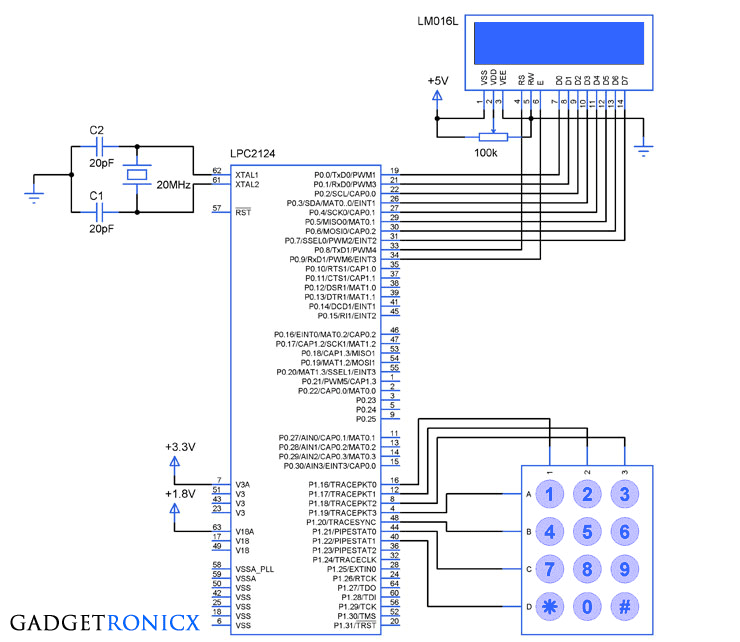

Enable(EN): This pin is used to send the enable trigger to LCD. After sending the data/cmd, Selecting the data/cmd register, Selecting the Write operation. An HIGH-to-LOW pulse has to be sent on this enable pin which will latch the info into the LCD register and triggers the LCD to act accordingly. Schematic Below schematic shows the minimum connection required for interfacing the LCD with the microcontroller. As we are interfacing the LCD in 4-bit mode, only the higher 4 data lines are used as the data bus. Port Connection This section shows how to configure the GPIO for interfacing the LCD.

Below table shows the LCD pins connection. RS RW EN D0 D1 D2 D3 D4 D5 D6 D7 P1_27 P_28 P_29 P1_16 P1_17 P1_18 P1_19 P1_20 P1_21 P1_22 P1_23 • P_NC: Pin Not Connected The below configuration is as per the above table. You can connect the LCD to any of the PORT pins available on your boards and update this section accordingly LCD Operation In this section, we are going to see how to send the data/cmd to the LCD along with the timing diagrams. First let's see the timing diagram for sending the data and the command signals(RS,RW,EN), accordingly, we write the algorithm and finally the code. Timing Diagram The below image shows the timing diagram for sending the data to the LCD. As shown in the timing diagram the data is written after sending the RS and RW signals. It is still ok to send the data before these signals.

The only important thing is the data should be available on the databus before generating the High-to-Low pulse on EN pin. Steps for Sending Command: • step1: Send the I/P command to LCD. • step2: Select the Control Register by making RS low. • step3: Select Write operation making RW low. • step4: Send a High-to-Low pulse on Enable PIN with some delay_us.

Steps for Sending Data: • step1: Send the character to LCD. Usb redirector rdp edition keygen software keys. • step2: Select the Data Register by making RS high. • step3: Select Write operation making RW low.